|

ROBOTIC WELDING AUTOMATION

(SUPPLIED TO PROTON MALAYSIA)

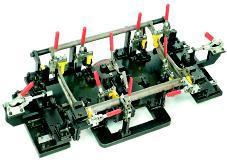

FIXTURES & INSPECTION JIGS FOR CROSS MEMBER ASSEMBLY AND LOWER ARM

* Welding Robot - 16 Nos. * Material Handling Robot - 01 No. * Welding Fixtures - 33 Nos.

* Inspection Jigs - 04 Nos. * Pick -Up Jig - 01 No.

* Final Assembly Fixture - Fully Automatic Welding Control thru PLC including loading and unloading

EQUIPMENT FOR EXHAUST SYSTEMS

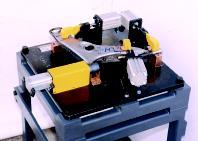

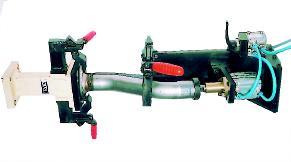

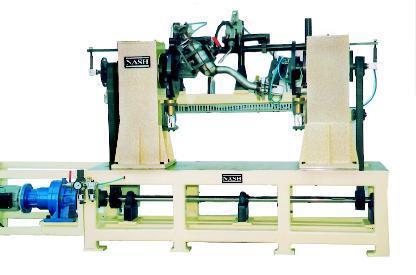

Horizontal SPM for circular welding of exhaust converter. |

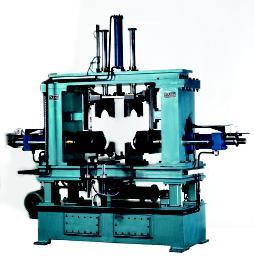

PLC controlled hydraulic canning press for catalytic converter assembly with robot interface.

|

PLC controlled vertical circular SPM for catalytic converter sub components. |

PLC controlled hydraulic Press for flanging operation of exhaust muffler. |

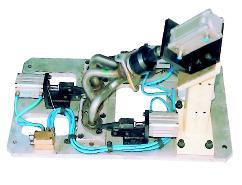

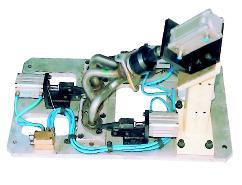

Leakage testing fixture for exhaust manifold. |

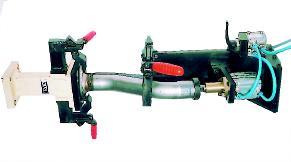

Fixture suitable for horizontal SPM. |

Fixture for flange with pipe welding suitable for horizontal SPM. |

Sub components for catalytic converter. |

SPECIAL PURPOSE MACHINES

|

|

|

|

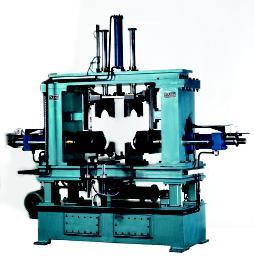

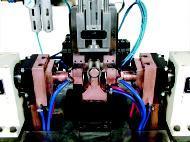

Servo Indexing Multi Spot Welder with self equalizing

Spot Welding Auto Guns for Back Plate and Dust Shield welding for

Automobile Brakes. |

SPECIAL PURPOSE MACHINES

|

Production Rate –

250 Nos. per hr.

|

|

| Semi-Automatic Dual Head

Multi Projection Welder for Shock Absorber Bracket

Assly. |

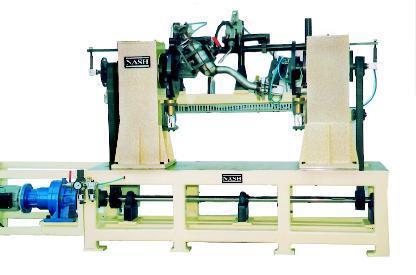

150 KVA Special Purpose Seam Welder for Strut and Shock Absorber Assembly

|

-

Specially designed for high speed production of

Struts and Shock Absorbers

-

Welding Heads with anti friction

bearings

-

Designed specially with large clear work area for

struts which also gives easy access for tool change, loading and

unloading

-

Machine will accept components with diameter of

30mm to 70mm and reservoir tube lengths of 150mm to 600mm

|

| |

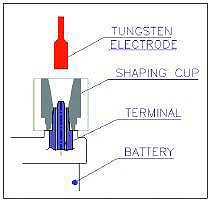

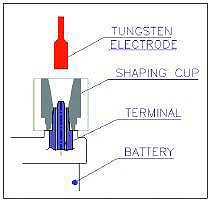

Battery Terminal Post Machine

|

|

SPM can be easily adaptable in

existing automatic production line. |

| |

ROBOTIC WELDING AUTOMATION

For TWO WHEELER SWING ARM ASSEMBLY |

|

- Full Utilisation of Robot

- Zero Loading and

Unloading Time

- Adequate Cooling Time

- Single Operator Requirement

|

ROBOTIC WELDING AUTOMATION For TWO WHEELER

Fuel Tank ASSEMBLY |

|

- Galvanized Sheets 0.8 mm thick

- Twin Clyinder Synchronous Movement

Hydraulic Special Purpose Press

- Interfacing of Welding Robot with

Hydraulic System thru PLC

- Loading and Unloading System for Tooling

- Low Changeover Time

- Equipped with all types of safety standards

Leak Testing Machine for fuel tank |

|

|